Basics I

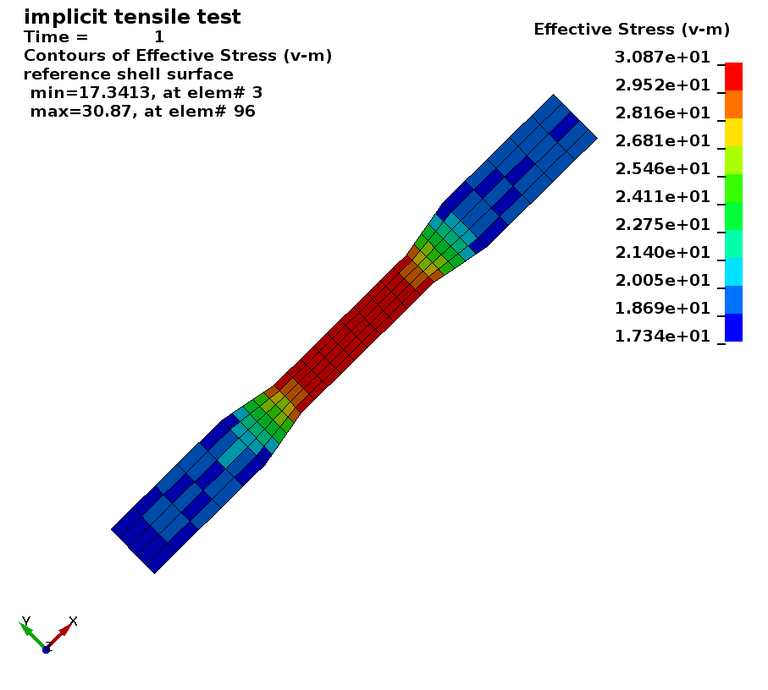

A static tensile test is simulated using shell elements. One end of the specimen is constrained, while concentrated nodal loads are applied at the other end. Uniform stresses develop in the narrowed center section.

https://www.dynaexamples.com/implicit/basic-examples/basics-i

https://www.dynaexamples.com/@@site-logo/LS-DYNA-Examples-Logo480x80.png

Basics I

A static tensile test is simulated using shell elements. One end of the specimen is constrained, while concentrated nodal loads are applied at the other end. Uniform stresses develop in the narrowed center section.

Problem #1: Tensile Test Objectives * Learn how to activate LS-DYNA implicit mode. * Learn how to select linear or nonlinear analysis. Problem Description A static tensile test is simulated using shell elements. One end of the specimen is constrained, while concentrated nodal loads are applied at the other end. Uniform stresses develop in the narrowed center section. Input Filename: tensile1.k Procedure Copy the input file to your local directory. Using an editor, view the input file and answer the following questions: 1. Which shell element formulation is used? 2. How many steps are used to apply the load? Run the simulation, and post-process using LS-POST. Record below the total applied load and total tip displacement (HINT: the ascii database NODFOR includes data for each of the tip nodes). 3. Applied load Tip displacement Modify the input deck to increase the applied load 100x, and rerun the simulation. Record the new data: 4. Applied load Tip displacement 5. Is the simulation linear or nonlinear ? (Does the tip displacement scale linearly with applied load?) 6. What types of nonlinearity exist in this problem? ( ) material ( ) geometric ( ) contact Modify the *CONTROL_IMPLICIT_SOLUTION keyword to perform a linear simulation, and record the results below for the large applied load: 7. Applied load Tip displacement 8. What is the reaction force at the fixed end of the beam? 9. Why does the reaction force not equal the applied load? Modify the input deck to use the linear element formulation type 21, and repeat the simulation. 10. Does the reaction force now match the applied load? ( ) yes ( ) no

*BOUNDARY_SPC_NODE *CONTROL_IMPLICIT_AUTO *CONTROL_IMPLICIT_GENERAL *CONTROL_IMPLICIT_SOLUTION *CONTROL_IMPLICIT_SOLVER *CONTROL_TERMINATION *DATABASE_BINARY_D3PLOT *DATABASE_EXTENT_BINARY *DATABASE_NODAL_FORCE_GROUP *DATABASE_NODFOR *DATABASE_NODOUT *DEFINE_CURVE *ELEMENT_SHELL *END *KEYWORD *load_node_point *MAT_elastic *NODE *PART *SECTION_SHELL *SET_NODE_LIST *TITLE

*KEYWORD

*TITLE

implicit tensile test

$

$ test coupon: 200 mm long, 20 mm width, 2.67 mm thickness, 50.8 mm gauge length

$

$ units; mm, s, ton, N

$

$ A. Tabiei

$

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

$

*CONTROL_TERMINATION

1.0000

$

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

$

*CONTROL_IMPLICIT_GENERAL

$ imflag dt0 iefs nstepsb igs

1 1.0 0 0 0

$

*CONTROL_IMPLICIT_SOLUTION

$ nlsolvr ilimit maxref dctol ectol rctol lstol

0 0 0 0.0 0.0 0 0

$ dnorm divflag inistif nlprint

0 0 0 0

$

*CONTROL_IMPLICIT_SOLVER

$ lsolvr prntflg negeig

0 0 0

$

*CONTROL_IMPLICIT_AUTO

$ iauto iteopt itewin dtmin dtmax

0 0 0 0.0 0.0

$

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

$

*DATABASE_EXTENT_BINARY

$ neiph neips maxint strflg sigflg epsflg rltflg engflg

1 1

$ cmpflg ieverp beamip

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

$

*DATABASE_BINARY_D3PLOT

0.010

*DATABASE_NODFOR

0.010

*DATABASE_NODOUT

0.010

*DATABASE_NODAL_FORCE_GROUP

2

*SET_NODE_LIST

2

30,31,32,33,38,39

$

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

$

*MAT_elastic

$ MID RO E PR

1 0.780E-08 0.207E+06 0.280E+00

$

*SECTION_SHELL

1 0

2.670E-00 2.670E-00 2.670E-00 2.670E-00

$

*PART

shell tensile strip

1 1 1

$

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

$

*DEFINE_CURVE

1

0.00000000000000E+00 0.0000000000000E+00

1.00000000000000E+00 2.0000000000000E+02

$

*load_node_point

$ Node DOF LCID SF

204 1 1 1

205 1 1 1

206 1 1 1

207 1 1 1

212 1 1 0.5

213 1 1 0.5

$

*BOUNDARY_SPC_NODE

30 0 1 1 1 1 1 1

31 0 1 1 1 1 1 1

32 0 1 1 1 1 1 1

33 0 1 1 1 1 1 1

38 0 1 1 1 1 1 1

39 0 1 1 1 1 1 1

$

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

$

*END