Advanced : Heart Valve

*ICFD_BOUNDARY_FSI

*ICFD_BOUNDARY_NONSLIP

*ICFD_BOUNDARY_PRESCRIBED_PRE

*ICFD_CONTROL_ADAPT_SIZE

*ICFD_CONTROL_EMBEDSHELL

*ICFD_CONTROL_FSI

*ICFD_CONTROL_MESH

*ICFD_CONTROL_OUTPUT

*ICFD_CONTROL_TIME

*ICFD_DATABASE_FLUX

*ICFD_DATABASE_FLUX

*ICFD_DATABASE_DRAG

*ICFD_MAT

*ICFD_PART

*ICFD_PART_VOL

*ICFD_SECTION

*MESH_EMBEDSHELL

*MESH_VOLUME

*KEYWORD MEMORY=100000000

*INCLUDE

mesh_cfd.k

*DEFINE_CURVE_TITLE

Inlet Pressure

$# lcid sidr sfa sfo offa offo dattyp lcint

1 0 1.0 1.0 0.0 0.0 0 0

$# a1 o1

0.0 0.0

0.006278 1333.432983

0.025112 6666.598145

0.054933 9999.613281

0.103587 13332.910156

0.1287 13332.910156

0.152242 13332.910156

0.169507 13332.910156

0.18834101 8888.797852

0.202466 -8888.513672

0.21031401 -27935.710938

0.238565 -73649.023438

0.26053801 -100314.898438

0.26681599 -109838.5

0.31390101 -109838.5

0.35470799 -102219.601563

0.40493301 -96505.609375

0.49910301 -97775.351563

0.56143498 -97775.351563

0.65560502 -97775.351563

0.759193 -93965.96875

0.80000001 -78410.71875

0.85000002 0.0

*DEFINE_CURVE_TITLE

Outlet Pressure

$# lcid sidr sfa sfo offa offo dattyp lcint

2 0 1.0 1.0 0.0 0.0 0 0

$# a1 o1

0.0 0.0

0.85000002 0.0

*ICFD_CONTROL_TIME

$# ttm dt cfl lcidsf dtmin dtmax

&end_t &dt_cfd 1.0 0 1e-5 1e-3

*ICFD_CONTROL_EMBEDSHELL

,,1

*ICFD_CONTROL_OUTPUT

4

*ICFD_CONTROL_MESH

1.6

*ICFD_CONTROL_ADAPT_SIZE

1,100

*ICFD_BOUNDARY_NONSLIP

$# pid

1

*ICFD_BOUNDARY_NONSLIP

$# pid

2

*ICFD_BOUNDARY_NONSLIP

$# pid

3

*ICFD_BOUNDARY_PRESCRIBED_PRE

$# pid lcid sf death birth

4 1 0.51.00000E28 0.0

*ICFD_BOUNDARY_PRESCRIBED_PRE

$# pid lcid sf death birth

5 2 1.01.00000E28 0.0

*ICFD_BOUNDARY_NONSLIP

$# pid

6

*ICFD_BOUNDARY_NONSLIP

$# pid

7

*ICFD_MAT

$# mid flg ro vis st thd

1 1 1.059 0.035 0.0

$----------------------------------------------

*ICFD_PART

$# pid secid mid

1 1 1

*ICFD_PART

$# pid secid mid

2 1 1

*ICFD_PART

$# pid secid mid

3 1 1

*ICFD_PART

$# pid secid mid

4 1 1

*ICFD_PART

$# pid secid mid

5 1 1

*ICFD_PART

$# pid secid mid

6 1 1

*ICFD_PART

$# pid secid mid

7 1 1

*ICFD_BOUNDARY_FSI

$# pid

3

*ICFD_CONTROL_FSI

$0,0.001,,,,,10

0

*ICFD_DATABASE_FLUX

$# pid

4

*ICFD_DATABASE_FLUX

$# pid

5

*ICFD_DATABASE_DRAG

$# pid

3

*ICFD_PART_VOL

$# pid secid mid

20 1 1

$# spid1 spid2 spid3 spid4 spid5 spid6 spid7

1 2 3 4 5 6 7

*ICFD_SECTION

$# sid

1

*MESH_EMBEDSHELL

$# volid

20

$# pid1

3

*MESH_VOLUME

$# volid

20

$# pid1 pid2 pid3 pid4 pid5 pid6

1 2 4 5 6 7

*END

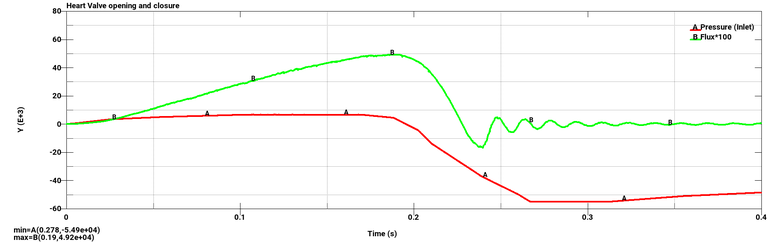

Thanks to its advanced and integrated fluid structure interaction capabilities, LS-DYNA's ICFD solver is capable of successfully solving highly non linear FSI problems such as artificial heart valves and addressing its numerous challenges :

- Strong pressure gradients : special stabilization techniques are developed in order to restrict spurious backflow which can occur in Pressure-Pressure boundary conditions.

- Similar solid and fluid material densities : strong FSI coupling is required. This requires solving the solid mechanics domain using an implicit solver and couple with the ICFD solver in a non linear iterative loop. See *CONTROL_IMPLICIT keywords and *ICFD_CONTROL_FSI/*ICFD_BOUNDARY_FSI

-Thin leaflets that undergo strong deformations : the solid mechanics LS-DYNA solver features advanced contact capabilities (See *CONTACT_..._MORTAR) which allows it to handle strong deformations and contact between thin structures.

- Extensive mesh deformation and frequent remeshing : One of the strengths of the ICFD solver is its capability of retaining a good quality solution even in highly distorted meshes or during remeshing. See ICFD_CONTROL_ADAPT_SIZE.

- Gap leakage treatment : See ICFD_CONTROL_EMBEDSHELL, the ICFD solver recently introduced the capability to shut off the flow leakage at non watertight embedded shell intersection points. This new approach effectively prevents any flow escapement once the leaflets have been forced shut.