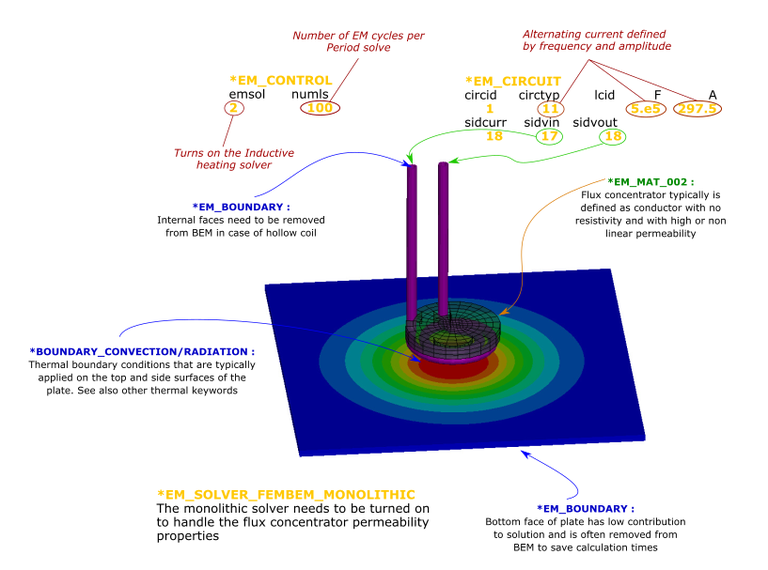

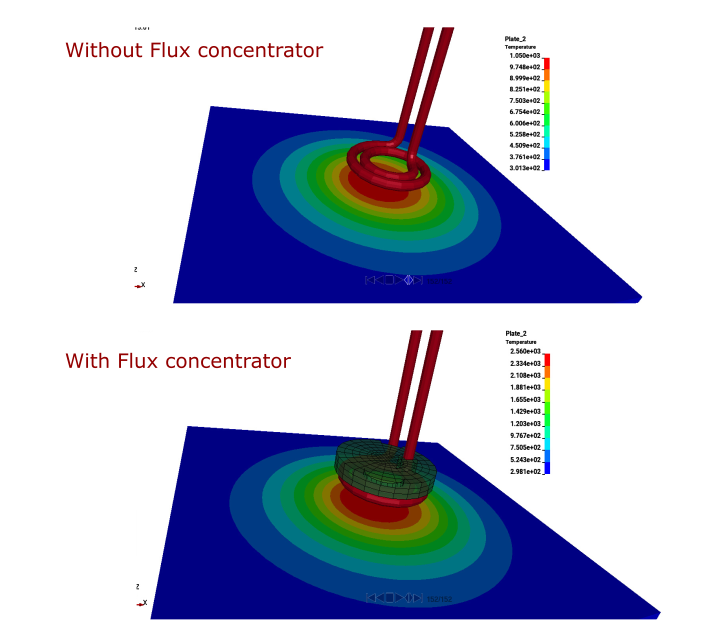

This LS-DYNA simulation shows a simple pancake coil + flux concentrator inductive heating problem. The Monolithic solver must be turned on in order to handle the zero conductivity/high permeability properties of the flux concentrator. Its presence allows a stronger concentration of the magnetic field close to the coil and therefore will generate more heat in the workpiece.

During the initial EM solve, a micro EM timestep is calculated using the circuit's current period divided by a factor NUMLS. Over a whole period, the full Eddy current problem is solved. An average Joule heating is calculated which is then given to the thermal solver over all the subsequent periods until reaching a time defined by a EM macro timestep. In this problem, the coil and the thermal material properties are considered constant so the EM macro timestep can be defined as the termination time. In cases involving moving coils or varying material properties, it is important to periodically update the average joule heating by defining this EM macro timestep.

Courtesy of : Dr. Miro Duhovic, Institut fur Verbundwerkstoffe(IVW) $GmbH, Kaiserslautern

*KEYWORD

*EM_BOUNDARY

*EM_BOUNDARY

*EM_CONTROL

*EM_CONTROL_TIMESTEP

*EM_CIRCUIT

*EM_MAT_001

*EM_MAT_002

*EM_MAT_002

*EM_OUTPUT

*EM_SOLVER_BEM

*EM_SOLVER_FEMBEM_MONOLITHIC

*END

*KEYWORD

*PARAMETER

$--------1---------2---------3---------4---------5---------6---------7---------8

$ EM

I numls 100

I femre 100

I bemre 100

R freq 5.e5

R amp 297.5

R murel 27.5

R em_dt 15.0

R sigCoil 60.e7

R sigFlux 0.

R sigPlate 25.e3

$--------1---------2---------3---------4---------5---------6---------7---------8

*EM_CONTROL

$--------1---------2---------3---------4---------5---------6---------7---------8

$ emsol numls emdtinit emdtmax emtinit emtend ncyclFem ncyclBem

2 &numls &femre &bemre

*EM_CONTROL_TIMESTEP

1,&em_dt

*EM_CIRCUIT

$--------1---------2---------3---------4---------5---------6---------7---------8

$ circId circType lcId R/F L/A C/t0 V0

1 11 0 &freq &

$# sidcurr sidvin sidvout partid

18 17 18

*EM_OUTPUT

$--------1---------2---------3---------4---------5---------6---------7---------8

$ matS matF solS solF mesh memory timing d3plotAsc

2 2 2 2

*EM_BOUNDARY

$--------1---------2---------3---------4---------5---------6---------7---------8

$ ssid btype

16 9

*EM_BOUNDARY

$--------1---------2---------3---------4---------5---------6---------7---------8

$ ssid btype

11 9

$Choice of BEM precond is important here and will impact calculation times

*EM_SOLVER_BEM

$# reltol maxite stype precon uselas ncyclbem

1.e-4 1000 2 4 1

*EM_SOLVER_FEMBEM_MONOLITHIC

$--------1---------2---------3---------4---------5---------6---------7---------8

$ MTYPE STYPE ABSTOL RELTOL MAXIT

0 0 1.e-08 1.e-4 100000

*EM_MAT_001

$--------1---------2---------3---------4---------5---------6---------7---------8

$# mid mtype sigma eosid murel eosmu deatht

1 2 &sigCoil

*EM_MAT_002

$--------1---------2---------3---------4---------5---------6---------7---------8

$ em_mid mtype sigma eos murel eosmurid

2 4 &sigPlate

*EM_MAT_002

$--------1---------2---------3---------4---------5---------6---------7---------8

$ em_mid mtype sigma eos murel eosmurid

3 4 &sigFlux 0 &murel

*END